Blog Detail

Graphix Media

Revolutionizing Cement Manufacturing with Advanced Analytics Software

Published on 2025-11-07 | Category: Industrial Software > Manufacturing / Automation

Introduction

In today’s competitive and sustainability-focused manufacturing world, the cement industry is turning toward data analytics and digital transformation to enhance performance and ... Read More

5min

Read Time

Revolutionizing Cement Manufacturing with Advanced Analytics Software

Introduction

In today’s competitive and sustainability-focused manufacturing world, the cement industry is turning toward data analytics and digital transformation to enhance performance and efficiency. Cement Plant Analytics Software is emerging as a game-changer — enabling plants to monitor, predict, and optimize every step of production with precision.

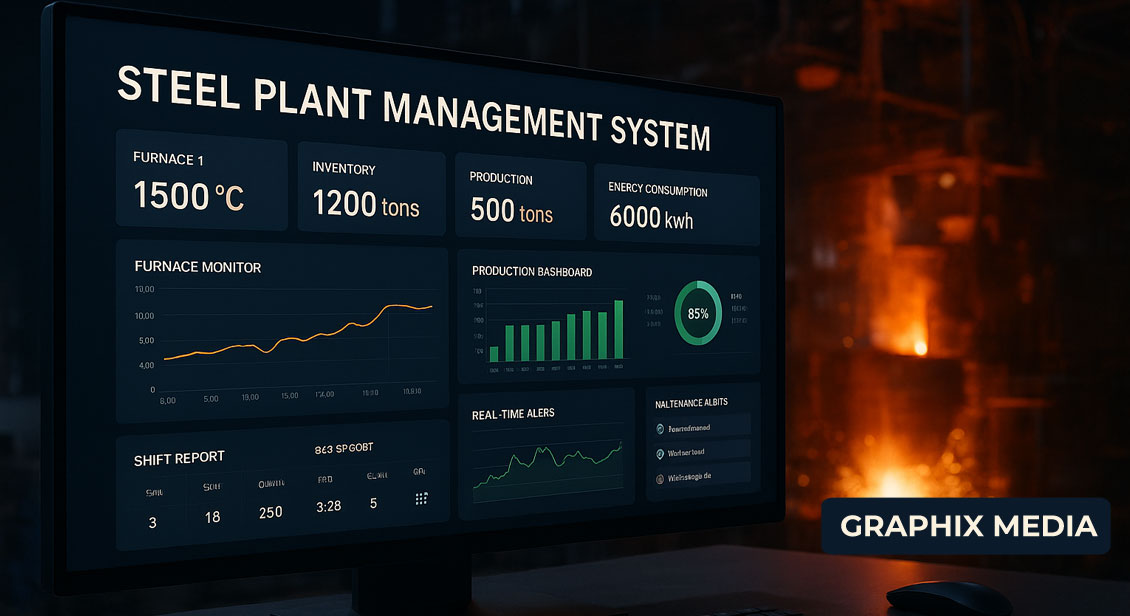

What Is Cement Plant Analytics Software?

Cement Plant Analytics Software is an integrated data intelligence platform designed to collect, process, and analyze information from multiple production points — from raw material handling to final packaging. It connects sensors, machines, and operators through a single digital ecosystem, helping decision-makers make smarter, faster, and more sustainable choices.

Key Features & Capabilities

-

Real-Time Monitoring

-

Live dashboards track kiln performance, energy consumption, temperature, and pressure parameters.

-

Alerts and notifications instantly highlight operational deviations.

-

-

Predictive Maintenance

-

Machine learning models forecast potential equipment failures before they occur.

-

This minimizes downtime, extends asset life, and reduces maintenance costs.

-

-

Process Optimization

-

AI-driven analytics identify inefficiencies in fuel usage, material blending, and production throughput.

-

Continuous process adjustments improve yield and quality consistency.

-

-

Energy & Sustainability Management

-

Energy usage and emissions data are analyzed to optimize energy mix and reduce carbon footprint.

-

Reports help align operations with ESG goals and green certifications.

-

-

Quality Control Automation

-

Advanced sensors and analytics ensure every batch meets defined quality parameters.

-

Reduces human error and enhances traceability.

-

Benefits for Cement Manufacturers

-

Higher Efficiency: Reduced production costs through better utilization of equipment and materials.

-

Improved Product Quality: Stable processes lead to consistent cement quality.

-

Energy Savings: Intelligent systems identify wastage and optimize fuel consumption.

-

Reduced Downtime: Predictive insights prevent unexpected equipment failures.

-

Sustainability: Lower emissions and improved energy management support green manufacturing initiatives.

Integration with Industry 4.0

Cement Plant Analytics Software is part of the Industry 4.0 revolution — blending IoT, AI, Cloud Computing, and Big Data Analytics into traditional manufacturing setups. It allows plant managers to transition from reactive to proactive decision-making, ensuring operations are always a step ahead.

Conclusion

The adoption of Cement Plant Analytics Software marks a pivotal shift for the cement industry — from manual control to smart, connected, and data-driven operations. As digital transformation accelerates, analytics will continue to define how cement plants achieve efficiency, sustainability, and profitability in the years ahead.