Blog Detail

Graphix Media

Steel Plant Management System: Revolutionizing Industrial Operations

Published on 2025-10-18 | Category: Industrial Software > Manufacturing / Automation

Introduction

Steel manufacturing involves highly complex workflows - from sourcing raw materials to refining, casting, and distribution. Managing these processes manually often leads to inefficienc... Read More

5min

Read Time

Steel Plant Management System: Revolutionizing Industrial Operations

Introduction

Steel manufacturing involves highly complex workflows - from sourcing raw materials to refining, casting, and distribution. Managing these processes manually often leads to inefficiencies, delays, and inconsistent product quality.

This is where Steel Plant Management Software comes in - a comprehensive industrial automation system designed to bring precision, transparency, and speed to every stage of production.

Challenges Faced by Steel Manufacturers

Before digitization, most steel producers struggled with:

-

Manual Data Entry: Paper logs and manual reporting created bottlenecks.

-

Inefficient Resource Planning: Lack of real-time visibility over raw material inventory and machine usage.

-

Unpredictable Downtime: No predictive maintenance tools to prevent equipment failures.

-

Energy Inefficiency: Excess fuel and power usage due to non-optimized production cycles.

Solution Overview

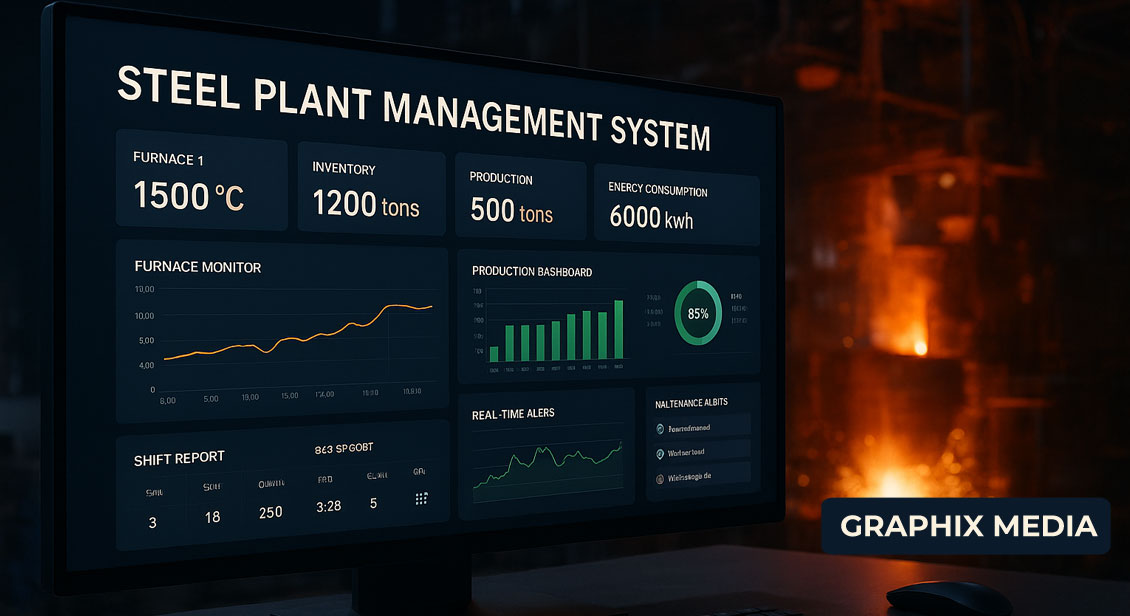

Our Steel Plant Management System integrates all production and operation activities into a single digital environment. From furnace monitoring and shift management to dispatch tracking and quality analytics - every aspect is automated and accessible in real-time.

This enables supervisors to make informed decisions, plan production efficiently, and respond quickly to anomalies.

Key Features

- Real-time Furnace & Temperature Monitoring

- Inventory & Logistics Integration with ERP

- Energy Consumption Analytics and reporting

- Maintenance Scheduler with predictive alerts

- Quality and Compliance Tracking

- Multi-user Roles (Admin, Operator, Supervisor)

- Data Visualization Dashboard for KPIs and trends

Results & Achievements

Companies implementing this solution have reported:

25% reduction in production downtime

20% increase in raw material utilization efficiency

Seamless integration with legacy ERP systems

Enhanced traceability from raw material to finished steel

Conclusion

Steel manufacturing is evolving rapidly, and those adopting smart digital tools are leading the race.

With our Steel Plant Management System, industries can not only streamline operations but also improve sustainability, data accuracy, and profit margins - setting new benchmarks for industrial efficiency.