Casestudy Detail

Graphix Media

COAL BLENDING MODEL

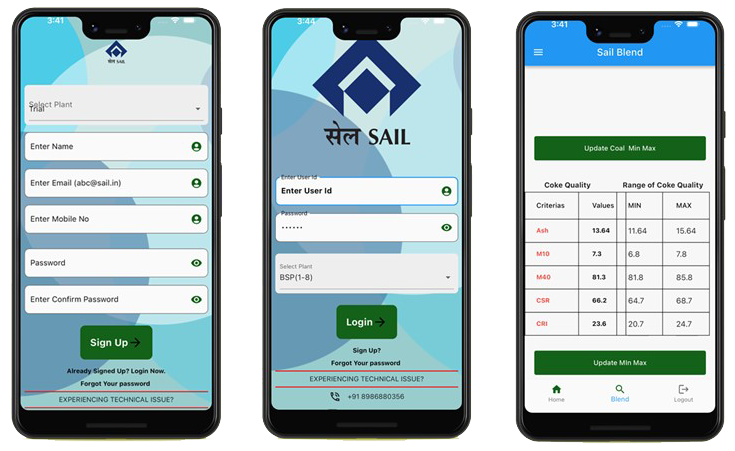

We developed a data-driven coal blending model designed to optimize the mixing of different coal grades based on quality, cost, and operational requirements. The system supports real-time analysis and...

6

weeks Project DurationApplication Visuals

Overview

We developed a data-driven coal blending model designed to optimize the mixing of different coal grades based on quality, cost, and operational requirements. The system supports real-time analysis and predictive outcomes, enabling industries to achieve efficient, cost-effective blends.

Key Features

Multi-Parameter Input System for Coal Grades, Properties & Constraints

Automated Blend Optimization Based on Quality & Cost Goals

Real-Time Quality Prediction of Final Blended Output

Cost Analysis & Side-by-Side Comparison of Blend Scenarios

Custom Blend Configuration with Option to Save & Reuse

Report Generation with Exportable Summaries & Charts

Interactive Dashboard for Data Visualization and Analysis

User Role Management for Secure Access

Scalable Design for Industrial Use Cases

Fast Computation Engine for Instant Feedback

Key Achievements

-

Improved operational efficiency through accurate blend recommendations

-

Reduced production costs with optimized blend combinations

-

Enabled real-time decision-making with predictive analysis

-

Enhanced planning with configurable and reusable blend setups

-

Streamlined reporting for audits and performance reviews

-

Delivered a user-friendly yet powerful industrial-grade tool

Challenges & Solutions

-

Data Accuracy & Migration:

Challenge: Converting old paper-based student records into the digital format.

Solution: Designed a custom data import tool with validation and cleanup processes. -

Multi-Level Access Control:

Challenge: Avoid data overlap or unauthorized edits by users.

Solution: Built a robust role-permission matrix system to segregate user capabilities. -

Result Processing Delays:

Challenge: Manual calculation and error-prone result entries.

Solution: Developed an automated grade calculation engine with real-time preview and bulk upload. -

Remote Coordination with Staff:

Challenge: Training university staff remotely during initial rollout.

Solution: Provided video tutorials, PDF user guides, and live remote sessions to ease the transition.